For automatically unloading the container, the system must identify the packages independently and create an unloading strategy corresponding to the packing pattern, according to which the unloading is then carried out. For this purpose, the system requires so-called suction gripper modules. With the help of vacuum technology, the packages are held and pulled out of the container. The following videos show how the gripper can change its height and move the suction grippers forwards or backwards.

The whole process of container loading is divided into six major steps. Steps one and two include the identification of the parquet stack as well as the approach and positioning of the system. Steps three to five involve the use of the presented suction gripper module.

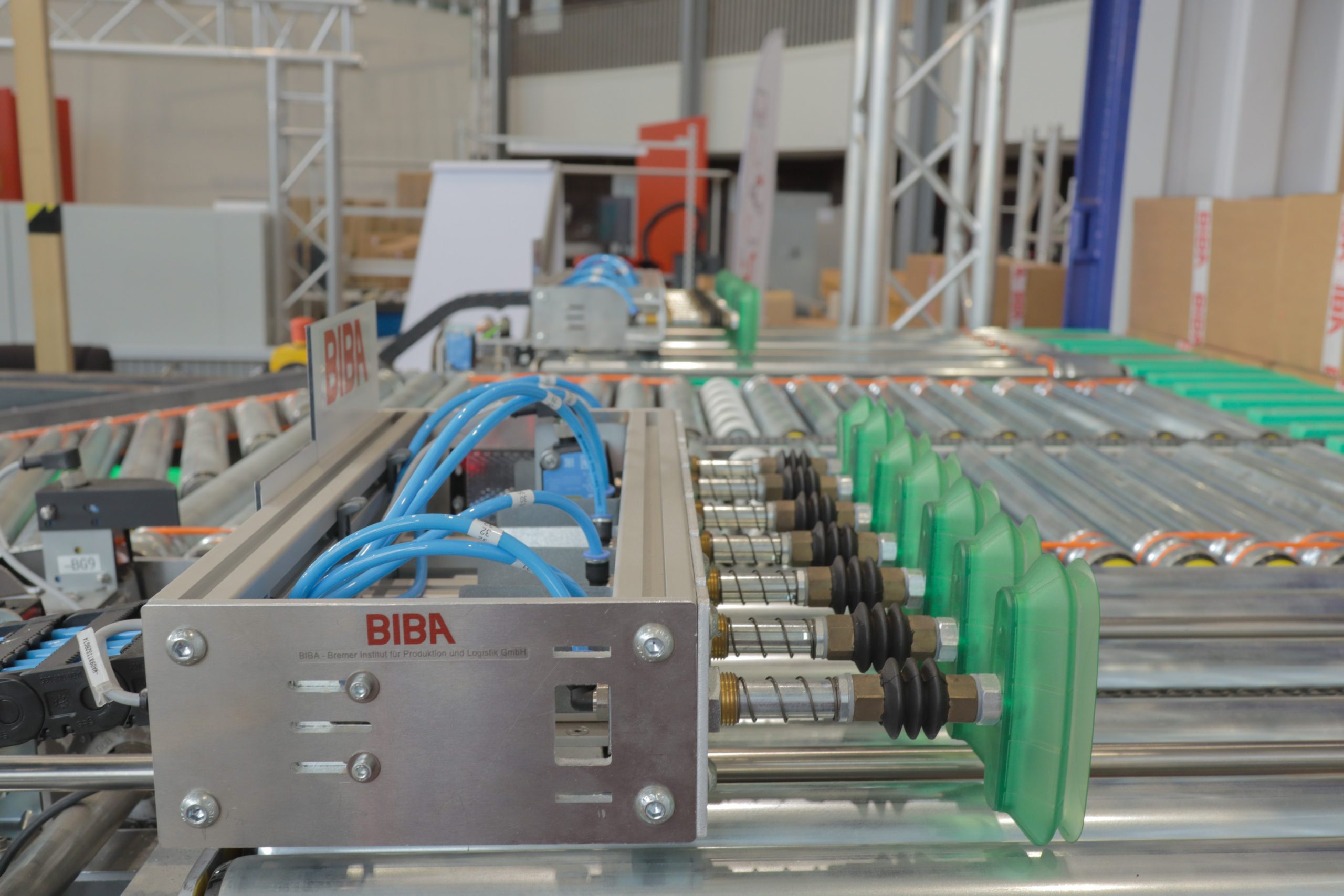

After positioning the gripper, it can grab the packages of a row, pull them out of the layer and deposit them on the conveyor system. The gripper consists of three individual segments, which in turn combine several vacuum grippers and thus enable the gripper to remove a complete row of packages from the layer in one step. To grip the packages, the segments are moved forward. Based on the identified packing pattern and the derived unloading strategy, the individual suction grippers are then activated individually to grip either individual packages or the entire row of packages from the layer.

The packages are then pulled out and deposited on the conveyor rollers by breaking the vacuum. The segments are then moved back to their initial position so that the next packages can be unloaded from the container.